#3dprinting #opensource #engineering #mechanical

https://ekunn.com

https://github.com/gregsaun

https://patreon.com/gregsaun

https://fosstodon.org/@bear_lab

➡️ www.dasfilament.de/filament-ref...

#3dprinting #dasfilament

➡️ www.dasfilament.de/filament-ref...

#3dprinting #dasfilament

➡️ github.com/Open-Resin-A...

#opensource

➡️ github.com/Open-Resin-A...

#opensource

Thank you @ptorrone.bsky.social ♥️

➡️ xcancel.com/ptorrone/sta...

#prusa #prusa3d #oshw #opensource #opensourcehardware

Thank you @ptorrone.bsky.social ♥️

➡️ xcancel.com/ptorrone/sta...

#prusa #prusa3d #oshw #opensource #opensourcehardware

➡️ certification.oshwa.org/ch000026.html

➡️ certification.oshwa.org/ch000027.html

➡️ certification.oshwa.org/ch000026.html

➡️ certification.oshwa.org/ch000027.html

(better later than never)

➡️ certification.oshwa.org/ch000025.html

#3dprinting #opensource #oshw #oshwa #prusa

(better later than never)

➡️ certification.oshwa.org/ch000025.html

#3dprinting #opensource #oshw #oshwa #prusa

- New resonance testing for input shaping

- New adaptive bed mesh leveling

- Add new sensors (eddy current, load cell, accelerometer, hall, temperature)

- Now support RP2350 microcontroller

And many more here :

www.klipper3d.org/Releases.html

- New resonance testing for input shaping

- New adaptive bed mesh leveling

- Add new sensors (eddy current, load cell, accelerometer, hall, temperature)

- Now support RP2350 microcontroller

And many more here :

www.klipper3d.org/Releases.html

- blue: their new "servo" motor

- yellow: the helical gear meshing with the "servo" motor gear. This is to drive the hobb gear

- red: the mechanism that put one of the filament in contact with the hobb gear. Each idler/tensioner is moving the filament passing through

- blue: their new "servo" motor

- yellow: the helical gear meshing with the "servo" motor gear. This is to drive the hobb gear

- red: the mechanism that put one of the filament in contact with the hobb gear. Each idler/tensioner is moving the filament passing through

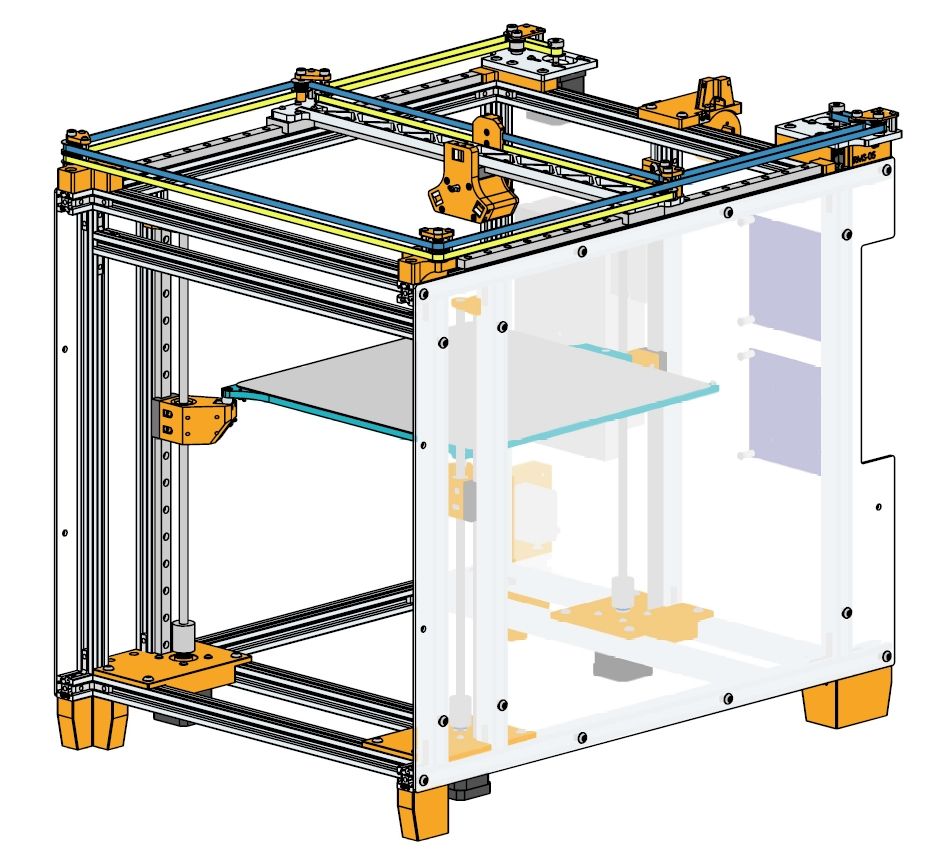

- Single print head with dual hotends (similar to UltiMaker)

- 350x320x325 build volume

- AMS with temperature & humidity control

- Swappable laser module

- Tinted window on the right side

Source: www.reddit.com/r/BambuLab/c...

- Single print head with dual hotends (similar to UltiMaker)

- 350x320x325 build volume

- AMS with temperature & humidity control

- Swappable laser module

- Tinted window on the right side

Source: www.reddit.com/r/BambuLab/c...

- Support Klipper and Marlin

- Robust components and connectors

- 5+1 steppers (expandable)

- Close loop capability

- Loads of IO

- 5V 10A for SBC

- 5V + 12V 5A for fans

➡️ github.com/BoltzRnD/Sma...

➡️ boltzrnd.com

- Support Klipper and Marlin

- Robust components and connectors

- 5+1 steppers (expandable)

- Close loop capability

- Loads of IO

- 5V 10A for SBC

- 5V + 12V 5A for fans

➡️ github.com/BoltzRnD/Sma...

➡️ boltzrnd.com

➡️ www.jubilee3d.com/index.php

➡️ github.com/machineagenc...

➡️ www.jubilee3d.com/index.php

➡️ github.com/machineagenc...

➡️ 3dprintingindustry.com/news/3d-prin...

➡️ 3dprintingindustry.com/news/3d-prin...

➡️ www.youtube.com/watch?v=7N3O...

Source: x.com/3Dable/statu...

#3dprinting #microsope #atom

➡️ www.youtube.com/watch?v=7N3O...

Source: x.com/3Dable/statu...

#3dprinting #microsope #atom

➡️ certification.oshwa.org/list.html?q=...

#OpenSource #oshwa #hardware

➡️ certification.oshwa.org/list.html?q=...

#OpenSource #oshwa #hardware